×

×

Introduction:

DERUNHUABANG is really a brand name well-known the industry of silica production. The business has introduced a thing new Hydrated Silica CAS 10279-57-9 Silicon Dioxide Hydrate Industrial Grade White Carbon Black High SiO2 for Rubber. This system is mainly based in the plastic industry, where it offers applications that are many.

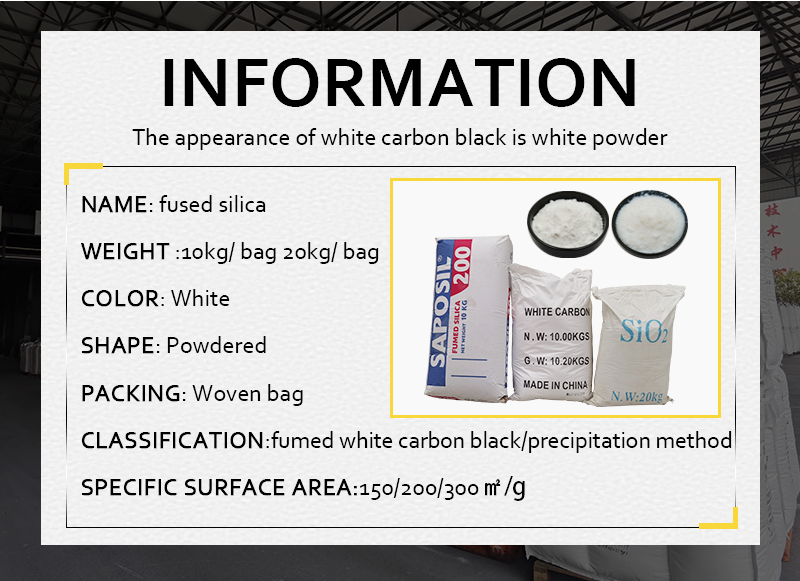

Physical Properties:

Hydrated Silica CAS 10279-57-9 Silicon Dioxide Hydrate Industrial Grade White Carbon Black High SiO2 for Rubber is a powder this is certainl white, which can be odorless. The merchandise is extremely fine in nature, insurance firms an particle typical ranging between 1-5 microns. The item comprises Silicon Dioxide Hydrate, that makes it an supply very good of and carbon.

Application:

Hydrated Silica CAS 10279-57-9 Silicon Dioxide Hydrate Industrial Grade White Carbon Black High SiO2 for Rubber is primarily utilized in the plastic industry, where the purposes are acted by it being after

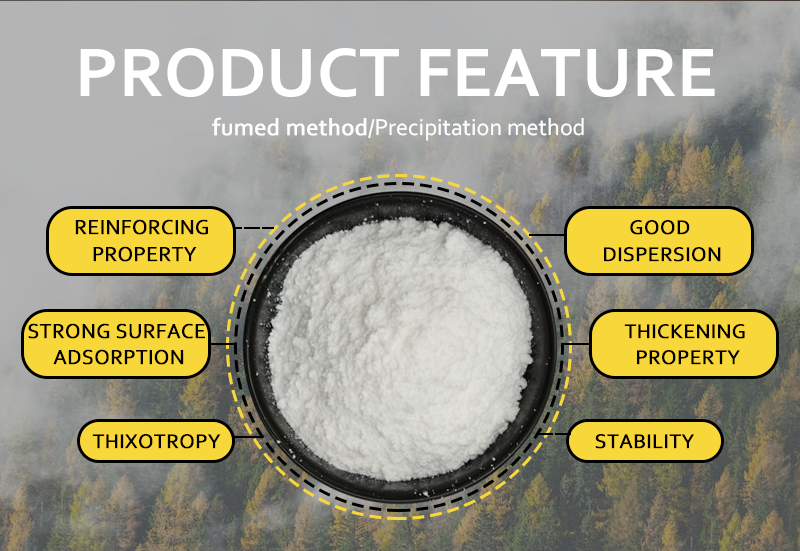

1. Reinforcement: Hydrated Silica CAS 10279-57-9 Silicon Dioxide Hydrate Industrial Grade White Carbon Black High SiO2 for Rubber advances the energy and durability in connection with plastic by reinforcing the carbon black colored and polymer matrix. This product is trusted in tire production, where it gives properties that are exceptional in terms of example increased use resistance, enhanced resistance rolling and better gas usage.

2. Abrasion Resistance: Hydrated Silica CAS 10279-57-9 Silicon Dioxide Hydrate Industrial Grade White Carbon Black High SiO2 for Rubber reinforces the rubber's real properties, that makes it tougher and even more resistant to hold and tear. The product is generally found in conveyor belts, gaskets, as well as other components that are plastic are subjected to high quantities of damage.

3. Electrical Insulation: Hydrated Silica CAS 10279-57-9 Silicon Dioxide Hydrate Industrial Grade White Carbon Black High SiO2 for Rubber displays exceptional electric insulation properties, making it beneficial in the industry electric. The item may be used within the production of electric cables, where it includes enhanced insulation and resistance to aging.

Benefits:

Hydrated Silica CAS 10279-57-9 Silicon Dioxide Hydrate Industrial Grade White Carbon Black High SiO2 for Rubber has advantages that are several that helps it be an option very good the plastic industry. A number of the benefits are:

1. High SiO2 Content: the item features a content most of Dioxide Hydrate, making it full of silica and carbon. The high SiO2 content provides enhanced physical properties such as increased energy, opposition to put up and tear, and enhanced insulation electric.

2. Excellent Reinforcement Properties: Hydrated Silica CAS 10279-57-9 Silicon Dioxide Hydrate Industrial Grade White Carbon Black High SiO2 for Rubber has reinforcement exemplary, rendering it a great item for the plastic industry. This product reinforces the carbon black colored and polymer matrix, enhancing the energy durability general of plastic.

3. economical: Hydrated Silica CAS 10279-57-9 Silicon Dioxide Hydrate Industrial Grade White Carbon Black High SiO2 for Rubber is a alternative economical other reinforcing agents employed in the plastic industry. The merchandise provides properties that are exceptional a lower cost, rendering it an option of interest the manufacturers.

Product Name |

White carbon black; Silicon dioxide; Silica; Hydrated silica |

Types |

precipitated white carbon black; fumed white carbon black |

Properities |

High temperature resistance, non-combustible, tasteless, odorless, and good electrical insulation. |

Usages |

anti-caking agent; adhesives; paint and coating extenders; rubber reinforcing agents; plastic tackifiers and thixotropic agents; thickeners for synthetic greases and silicone greases; filler in paper, Daily Chemicals etc. |